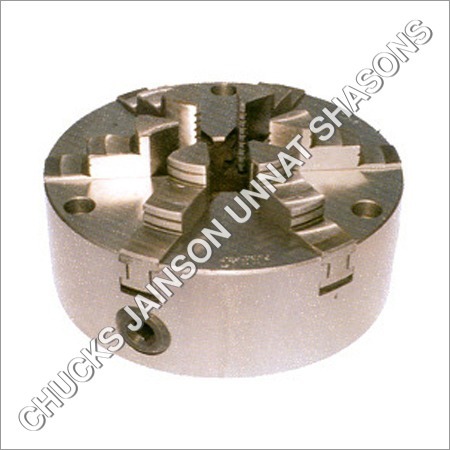

165 MM Six Jaw Chuck

Product Details:

165 MM Six Jaw Chuck Price And Quantity

- 5000 INR/Piece

- 1 Piece

165 MM Six Jaw Chuck Trade Information

- 500 Piece Per Day

- Days

Product Description

Owing to our in-depth expertise in this domain, we are engaged in offering an extensive array of Six Jaw Chuck. The higher rigidity and wear resistance enable the chuck to withstand higher machining forces. It is a compact tool, used in lathe, milling, vehicles and in solar panels. To meet the variegated requirements of our customers, we offer this Six Jaw Chuck in several specifications at marginal price.

Features:

- Low vibration

- Hardened and ground working surfaces

- Balanced scroll plate allows higher rotation speeds

Technical Specifications

Size | d1 | d2 | d3 | d4 | d5 | d6 | h1 | k | t | Approx Gross Wt. in kgs |

| 80 mm | 82 | 71 | 62 | M-6 | 19 | M-5 | 43 | 6 | 3 | 2 |

| 100 mm | 102 | 87 | 76 | M-8 | 23 | M-6 | 48 | 8 | 3 | 3 |

| 125 mm | 125 | 108 | 95 | M-8 | 32 | M-6 | 55 | 9 | 4 | 5 |

| 160 mm | 160 | 140 | 125 | M-10 | 42 | M-10 | 65 | 10 | 4 | 9 |

| 200 mm | 200 | 176 | 160 | M-10 | 55 | M-10 | 73 | 11 | 4 | 16 |

| 250 mm | 250 | 224 | 200 | M-12 | 76 | M-12 | 78 | 12 | 5 | 30 |

| 315 mm | 315 | 286 | 260 | M-16 | 103 | M-12 | 90 | 14 | 5 | 50 |

Body : High tensile strength , wear resistant cast iron with front and back mounting bolts.

Scroll : Alloy steel hardened scroll with thread ground from both sides.

Jaws : Case hardened steel , precisely ground for accuracy.

Pinion : Alloy steel hardened.

Standard Accessories

- A set of reverse jaws

- Key handle

- Front mounting bolts

|

JAINSON SALES CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese